Spring Cleaning for Your Warehouse: Optimize Your Racking System for Safety, Space, and Efficiency

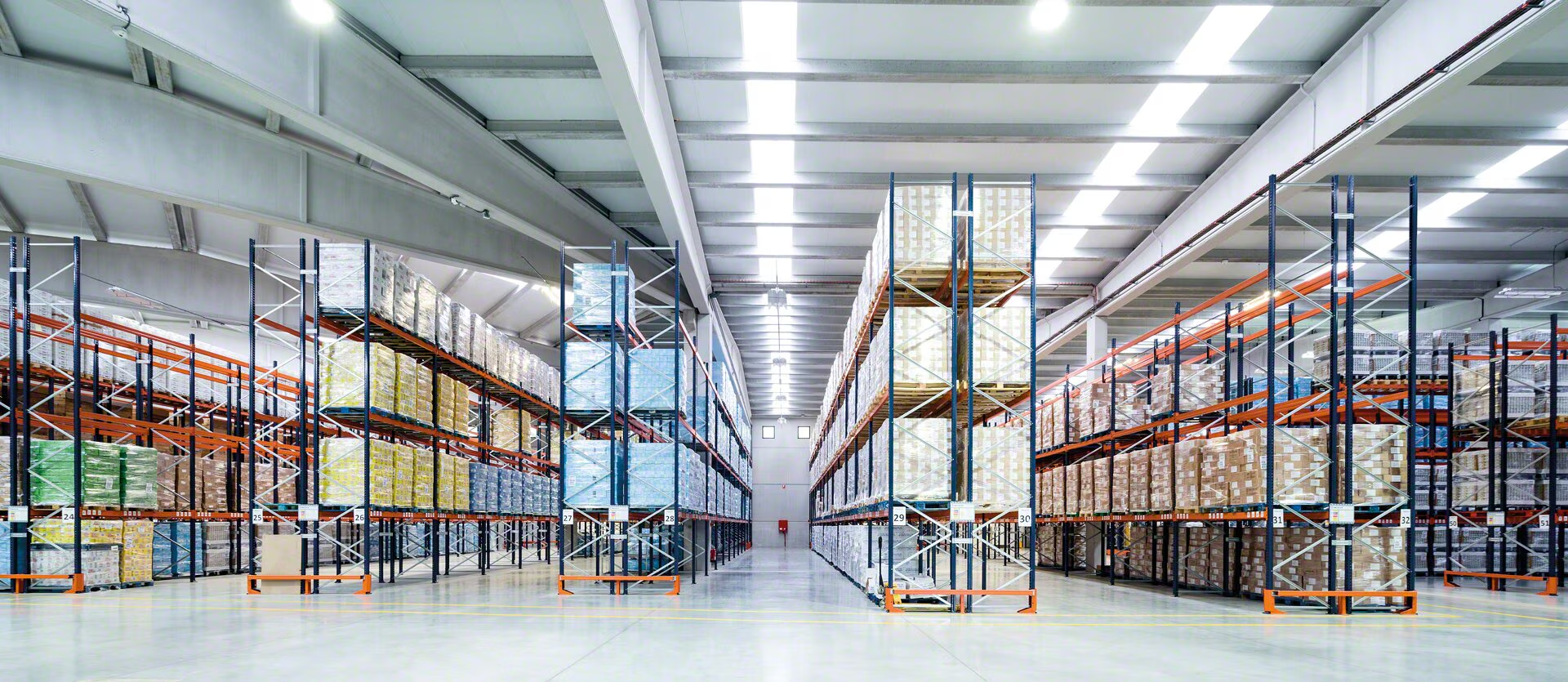

As winter fades and the days grow longer, spring is the perfect time to take a fresh look at your warehouse operations. Just like your home benefits from a thorough spring cleaning, your warehouse can too — especially your racking system. A clean, organized, and optimized racking setup can boost efficiency, improve safety, and free up valuable space.

In this article, we’ll walk you through practical steps to spring clean and optimize your pallet racking system for a smoother, safer, and more productive operation.

Why Spring Cleaning Your Warehouse Matters

Warehouse clutter doesn’t just look bad — it can lead to:

- Slower order fulfillment

- Increased risk of accidents

- Lost inventory

- Damaged equipment

- Poor first impressions for clients or inspectors

Spring cleaning offers an opportunity to reset, assess your current system, and make smart upgrades.

Step 1: Clear Out the Clutter

Start with a thorough cleanout of your space. Get your team involved and remove anything that doesn’t serve a purpose.

Tasks to tackle:

- Discard obsolete inventory or donate it

- Sweep, vacuum, and dust hard-to-reach racking areas

- Remove broken pallets and unused equipment

- Clean up spills and fix leaks

Step 2: Inspect Your Racking System for Damage

Before optimizing, ensure your current racking system is safe and functional.

Inspection checklist:

- Look for rust, corrosion, or bent beams

- Check for missing bolts or loose anchors

- Inspect load labels and capacity signage

- Identify damaged uprights or connectors

- Ensure everything complies with OSHA standards

If you spot any structural damage, don’t delay repairs. Your racking is only as strong as its weakest component.

Step 3: Reevaluate Your Layout

After cleaning and inspections, take a step back and evaluate your warehouse layout. Is it working for your current operations?

Questions to consider:

- Are fast-moving items easy to access?

- Is vertical space being fully utilized?

- Are aisles wide enough for forklift operation

- Are there bottlenecks in traffic flow?

Step 4: Optimize with Strategic Reorganization

A refreshed layout can lead to major efficiency gains. Use this opportunity to reorganize your racking system based on usage and demand.

Reorganization tips:

- Use ABC analysis to organize inventory (A = high-demand, C = low-demand)

- Store frequently picked items closer to shipping areas

- Group similar SKUs together to reduce picking time

- Adjust shelf heights to reduce wasted space

Step 5: Upgrade Where Needed

Spring cleaning is a great time to upgrade your equipment to support growing inventory or streamline operations.

Consider upgrading to:

- Teardrop pallet racks for easy adjustability and compatibility

- Cantilever racks for long or awkward items

- Push-back or pallet flow systems for higher density storage

- Wire decking for better fire safety and product support

Need help with rack selection? Pallet Rack Systems offers expert advice and nationwide installation.

Step 6: Establish a Maintenance Routine

The benefits of spring cleaning shouldn’t end in April. Establish a regular maintenance routine to keep your racking system in top condition year-round.

Maintenance checklist:

- Monthly visual inspections

- Quarterly deep cleaning of rack areas

- Annual professional rack inspection

- Regular employee training on safe use of racking systems

Ready to Refresh Your Racking?

Spring is the ideal time to reset and optimize your warehouse. Whether you need a simple reorganization or a complete racking overhaul, Pallet Rack Systems is here to help.

We specialize in custom pallet racking solutions, professional installation, and expert consulting — all backed by decades of experience.